Electric ferry gets off to a great start with DEIF solution

In 2021, Danish ferry operator Molslinjen added an electric ferry to its Esbjerg-Fanø route to boost service reliability and minimise environmental impact. A DEIF solution including a Delomatic 4 power and energy management system plus competent project support has helped make the switch from diesel to electric propulsion very successful. One captain considers the system very easy to use, and the project superintendent ranks the experience as the best new ship project he has been involved in.

Off the west coast of Jutland, Denmark, lies the scenic island of Fanø at the northern end of the shallow Wadden Sea. Even though Fanø is only a couple of kilometres from the busy port city of Esbjerg on the mainland, there has never been a bridge to the island; instead, its 3,500 inhabitants and thousands of annual visitors depend on a ferry service. Since 2018, the Esbjerg-Fanø crossing has been operated by Danish ferry company Molslinjen which provides reliable ferry services for daily commuters and tourists alike. The need for reliability and safety is underscored by the fact that the ferry is an integral part of the island’s emergency response system, always ready to take patients to hospital on the mainland.

“Every once in a while, accidents happen, and we’re constantly on standby for ambulances,” says captain Iben Gejl Christensen who has sailed the route since 2003. “When the ambulance arrives, we depart immediately.”

New electric ferry with DEIF system on board

In 2021, Molslinjen decided to boost the reliability of the ferry service by reducing the workload for its two existing ferries, the Fenja and Menja, and at the same time minimise its environmental impact by adding a third ferry, the electric Grotte. The batteries on the new ferry power two 375 kW electric motors that take up to 35 cars and 300 passengers across at a service speed of 11.5 knots. The Grotte recharges its batteries from a 2 x 1,250 kW shore supply during each 8-minute stay in the port of Esbjerg; this provides the necessary energy for a purely electric round trip.

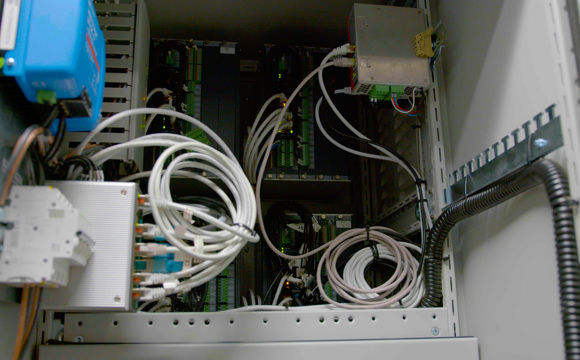

The electrical installations on board were handled by installation company Vest-El who used the DEIF Delomatic 4 power and energy management system to control and coordinate the power generating equipment on board and the connection to shore. In addition, DEIF contributed technical support and know-how throughout the project to ensure successful completion.

Easy to put into service

The Grotte has been in service since 1 October 2021 and both crews and management are happy with the new ship – and its control systems. Even though sailing on electrical power is different from sailing on diesel power, Iben Gejl Christensen has not had difficulties adjusting to the new system.

“I think it’s simple to work with,” she says. “It’s very manageable. We just need to press two buttons to start charging and two buttons to prepare for departure. I was able to learn, so I guess most other people could, too,” she adds with a smile.

Superintendent Thomas Jensen from Molslinjen is responsible for daily operations on the crossing and has been involved in the Grotte project since its early stages. He agrees that putting the new ferry into service has been relatively easy. “The commissioning went without any incidents,” he says. “Of course, we had to test the charging procedure at night to avoid disturbing operations. We spent three or four nights getting things ready, and I think it went well.”

State-of-the-art power and energy management

The Delomatic 4 system on the Grotte is a state-of-the-art power and energy management system that can be customised and engineered to fit a wide range of specifications and requirements. It is a perfect match for marine hybrid applications such as battery solutions and DC bus solutions, and the system can be monitored and controlled from multiple operator touch screens.

These features make the system a perfect match for the Grotte with its energy storage systems and DC bus. The control system on the ferry includes features for both daily operations and maintenance and can easily be accessed from 15” touch screens mounted on the bridge and in the two engine rooms. DEIF and Molslinjen staff can also access the system remotely to carry out monitoring or troubleshooting over a secure internet connection. The system provides facility management for the battery management system and displays important battery alarms on the operator touch screens, and it allows the crew to easily switch and manage batteries and inverters.

“We use the DEIF systems for power and energy management,” explains Thomas Jensen. “It’s very easy to connect engines, shore power, and charging power out there. Our navigators use the DEIF setups for battery, power, and energy management, and we use them in connection with maintenance and connecting and disconnecting the engines and motors. It works well.”

Thomas Jensen, Superintendent Molslinjen

Quiet and easy daily operations

On the daily crossings, the captain and first mate take turns at the controls for a round trip, alternately overseeing loading and unloading and deck operations. The crew also includes an able ship’s assistant and an ordinary ship’s assistant.

“We don’t really notice the battery operation, except that we can’t hear the engines or see any smoke from the exhaust”, says Iben Gejl Christensen. “Of course, we need to keep an eye on the state of charge, but apart from that it hasn’t been a big challenge to adjust to battery operations. It’s quiet on board – really quiet, in fact, and our passengers notice that, too”.

When the Grotte is in port in Esbjerg, the crew can easily start and stop the charging procedure by pressing buttons on the touch screen. A hatch on the side of the ship is opened, and the charging system plug is lowered towards the hatch and automatically grabbed and plugged into the ferry socket. After charging, the plug is ejected and hoisted away from the ship, the hatch closes, and the propulsion system is ready for departure. If the state of charge drops below 56% at sea, the diesel engine is started automatically to recharge the battery in order to comply with international maritime safety regulations.

A good overview with no distractions

The 12-minute crossing goes through a narrow trench with little space to give way, and deeper waters right outside the port of Esbjerg where there is often heavy traffic. To ensure safe passage, the crew needs to manoeuvre constantly during the crossing. This is one of the reasons why the Grotte was purposely designed to resemble the Fenja and the Menja.

“That’s what we wanted,” comments Iben Gejl Christensen. “If we were to have a new ferry, it needed to resemble the existing ones as much as possible so we could just get on board and sail off immediately”. Thomas Jensen adds, “The Grotte uses the same ramp system, and it’s important to us that we can use it alongside the Fenja and the Menja.”

The bridge layout and instrumentation are also very similar to those found on the existing ferries, but with one key difference: The 15” touch screen provides a good overview of every important aspect of the crossing. “It took us a little while to realise that we could see everything on one screen, and that we didn’t need to go down to the engine room,” remarks Iben Gejl Christensen. “I think it provides a good overview, and it doesn’t distract us from our operations while we’re sailing back and forth.”

Contributing to greener shipping

When the Grotte was put into service, Danish Minister for Transport Benny Engelbrecht was one of several guests who attended the official launch event, indicating the significance of battery-powered vessels as a means to contribute to lower carbon emissions from shipping. Similarly, the ferry is a perfect match for Molslinjen’s corporate social responsibility policy which calls for responsible conduct while contributing to freedom of movement: Molslinjen is continuously working to identify, prevent, or mitigate adverse impacts on sustainable development, and the Grotte proves that this can be achieved without adversely affecting the ferry timetable, or jeopardising safety on board.

“Our primary target was to get a green solution,” says Thomas Jensen. “We want to be seen as an innovative and sustainably managed transportation company. Molslinjen wants to develop battery operations on its shorter routes in western Denmark. We believe that getting this crossing to work was a good start, and everything indicates that we will succeed so we’re ready to upgrade our other routes with something similar to this. Bigger, of course, but similar!”

Off to a great start

Since 1 October 2021, the Grotte has been in operation with no significant cancellations or delays, marking a great start for the electric ferry which is now handling the passenger load alongside the Fenja and Menja and ensuring reliable, green, and safe transportation through the UNESCO world heritage waters between Esbjerg and Fanø. Despite the new propulsion solutions below deck, however, not much has changed on the bridge.

“The new world of electric operation has not changed the crossing itself,” says Iben Gejl Christensen. “We’re doing the same thing that we always have: We sail back and forth and make sure our customers get to and from the island. We just need to focus on some other things. I think it’s really easy to use the DEIF system because we can’t really make mistakes. It has to be that way – it has to be simple and easy. We shouldn’t have to press all kinds of menus to charge or stop charging or check how much power we’ve got on the batteries. It works well!”

Good performance with competent support

Throughout the project, DEIF has supported the Delomatic 4 system with know-how and practical technical solutions based on the company’s extensive experience from all types of marine power applications, including electric and hybrid propulsion solutions. These competences have contributed to a smooth project process where issues and challenges have been resolved quickly through a good and open dialogue between Molslinjen and DEIF. Speaking from a manager’s perspective, Thomas Jensen is very satisfied with the overall DEIF solution.

“I think DEIF has performed well,” he says. “In the project phase, the start-up phase, and the operational phase, they’ve been receptive to the changes we have suggested. It’s important that the people who are going to use the system every day can contribute. Overall, this is one of the best projects I’ve been involved in. I’ve had four or five projects before, but this is one of the best ones”. He stops briefly to think and then concludes, “It’s the best one.”

Thomas Jensen, Superintendent Molslinjen

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark -

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark